Bedford Pumps, the UK’s leading manufacturer of high capacity pumps for land drainage and flood control, has been awarded a prestigious contract to supply fish friendly concrete casing pumpsets for a new pumping station at Islington.

Islington Pumping Station (P.S.) is a historic pumping station located in Kings Lynn, Norfolk. It is owned and operated by Kings Lynn Internal Drainage Board (IDB) to pump water from the IDB’s drain to the tidal salt marshes of The Wash. The pumping station provides protection to almost 6000 hectares, making it the largest single catchment within the Board’s district. The catchment is largely fenland so consequently water is drawn to the station through the action of the pumps rather than gravity fed.

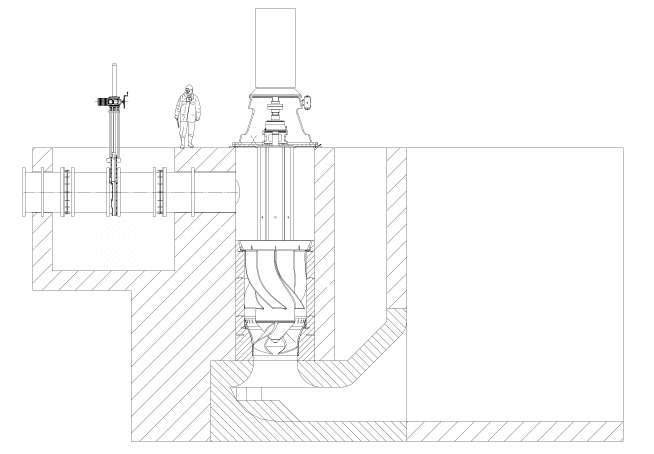

The existing pumping station at Islington was constructed in 1959 and operated with three diesel engine powered pumps rated at 2,800 l/s each. The pumping station has now reached the end of its service life and will be demolished following the construction of the new build station which will be situated at the end of the “Straight Mile”.

The new station will have a total pumping capacity of 16,000 l/s and is designed around four concrete casing pumps operating at a capacity of 4,000 l/s per pump; to put this into perspective, running at full capacity the pumping station would be capable of pumping 1.4 billion litres of water per day.

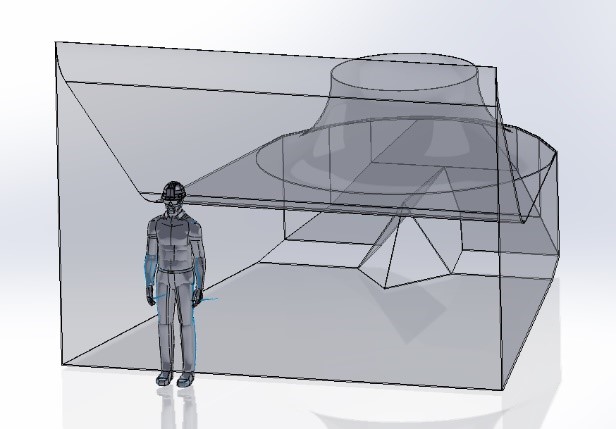

The pump casing is of a concrete cast construction and is designed to operate with a formed suction intake specifically designed by Bedford Pumps Ltd. The vast suction intake (pictured Fig 3. to scale) was scale model tested and optimised at Hydrotec Consultants Ltd.’s laboratory, operating at a total station capacity of 20,000 litres per second, thus proving the infrastructure future proof. The results were outstanding, with uniform flow patterns at the impeller inlet and free from pre-swirl, entrained air and surface and submerged vortices. The model test showed that the intake design allowed for incredibly low minimum operating water levels. The Bedford Pumps intake design offers significant advantages over a standard ANSI ‘type 10’ intake such as a significant reduction in the overall footprint and allowing the water levels to be drawn down to half the minimum submergence when compared to the type 10 design. The unique combined design of the pumps and the intake provides a very low footprint and will significantly reduce the excavation costs on site by allowing the pipework to be much closer to the surface. The formed suction intake will be constructed on site using very precise 3D printed polyform formers, allowing the civils contractor to accurately create the concrete intake.

The four pumpsets also fulfil the requirement for Islington P.S. to be “Fish Friendly”. Althoug ill-defined, the term ‘Fish Friendly’ implies a machine which avoids or minimises damage to aquatic fauna. In order for fish (and migratory eels) to pass through any form of rotodynamic pump, it is recognised that conventional pump designs require substantial modification and the range and extent to which a pump can be utilised is in fact relatively narrow. The particular elements within the pump to achieve these aims is obviously subject to company intellectual property but can be briefly summarised as follows.

To achieve a Fish-Friendly status, the essential elements for pumps include:

As part of the wider scope of the specific application:

Bedford Pumps have been satisfying the market need for Fish Friendly pumps for almost a decade and now have more than 100 operating units operating in virtually every corner of the world. They are delighted to be working with contractors Balfour Beatty at Islington, King’s Lynn’s largest pumping station. The project start date was 25th June 2019 and the completion date is 31st March 2021 and Bedford Pumps scope of supply is the pumps, installation, commissioning and site verification testing.

Bedford Pumps are a flexible, highly experienced manufacturer of robust pumping plant for the water industry, and one of the few UK manufacturers with a predominantly British supply chain, who will also benefit from this prestigious contract award.